Economic Feasibility of Solar Powered Methanol Production

Methanol Production Powered by Solar Power

The purpose of this project is to design and analyze the economic feasibility of constructing a methanol production facility that is powered by solar-thermal energy. The solar process used has an advantage over other technologies in that it does not produce tar byproducts, which are costly to remove in non-solar-thermal processes, additionally this process is much more environmentally friendly, compared to the current practice of using fossil fuels for energy uses.

This project uses a variety of computational methods for calculating the design, instrumentation and process controls of the chemical processes and reactions; costing & sizing of the equipment; solar reactor energy requirements and reactor design; using multivariate data analysis & chemical process optimization software. Economic and financial models for the creation of projections, expected trends and forecasts. The use of industry comparisons, ratio analysis, scenario/sensitivity and IRR returns analysis, were used to determine overall profitability over a 16-year period.

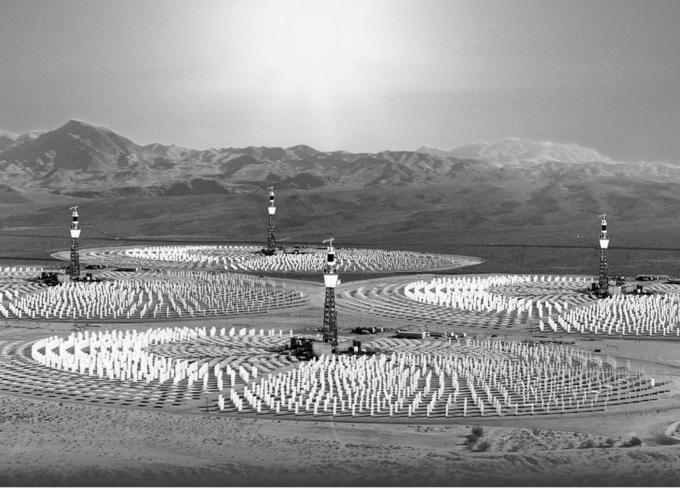

The project’s objective is an annual production of 56 million gallons of fuel grade methanol. Seventy acres of 4000 concentrated sun heliostats with a secondary radiation recovery mirror will provide an estimated 553GW-hr annually to the solar reactor.

The economic feasibility was analyzed over a 16-year period, which includes one year for plant construction. Total permanent investment (TPI) of capital into the project is approximately $294 MM with a working capital requirement of $31.58 MM. In order to achieve a 12.5% investor’s rate of return (IRR) the selling price of methanol is calculated to be $1.56/gal. Returns on investment (ROI) and corresponding payback period are 15.4% and 6.5 years respectively. The net present value (NPV) at the end of the first year is $203.02 MM. Given a market price of $1.13/gallon, the process is not economically viable given the current economic conditions.

ACKNOWLEDGEMENTS: DR. ALAN WEIMER of the University of Colorado assisted with the solar reactor and chemical process modeling